We’ve been fascinated by fully autonomous factories for years. They offer the potential for entirely self-sufficient production in industries ranging from automotive and pharmaceuticals to food, electronics, and beyond. The world has also increasingly started to become more interested in emerging autonomous technologies to help us combat a seemingly never-ending series of once-in-a-century events like the COVID-19 pandemic, aging populations, labor shortages, climate change, and international conflicts.

All of these have put major strain on our societies and the international supply chain as companies rapidly adapt their operations to tackle each new oncoming challenge. In this article, we’ll be covering the increasing prevalence of autonomous and dark factories, including the reasons why some are opposed to the rise in these AI-powered industrial robots and why this change is still needed to sustain the future of a rapidly changing manufacturing industry.

To better understand the conversations surrounding dark factories, it’s a good idea to know exactly what these are beyond an intuitive definition:

A dark factory is a type of factory that uses autonomous machines for production and no longer needs human involvement to produce goods. The controversy surrounding them includes potentially eliminating the jobs of former employees that used to be needed for production. On the other hand, factory owners counter this complaint by citing the ongoing global labor shortage as one of the main drivers for automation, allowing current employees to work alongside robots to improve the overall efficiency of operations.

Still, in the 2023 Future of Jobs Report 2023, the World Economic Forum (WEF) found that some technologies like non-humanoid robots will lead to the disappearance of jobs:

In the next five years, 83 million jobs are projected to be lost and 69 million are projected to be created, constituting a structural labour-market churn of 152 million jobs, or 23% of the 673 million employees in the data set being studied. This constitutes a reduction in employment of 14 million jobs, or 2%.

While this is a significant loss of jobs, the impact on the labor market might be less than you’d initially think. This is because the number of people retiring (in developed countries) exceeds the total number of jobs lost, resulting in a labor market that isn’t large enough to cover demand. In essence, despite this decline, businesses in developed countries will still face an ongoing labor shortage. But how is this possible?

Labor shortages and an aging workforce require automation

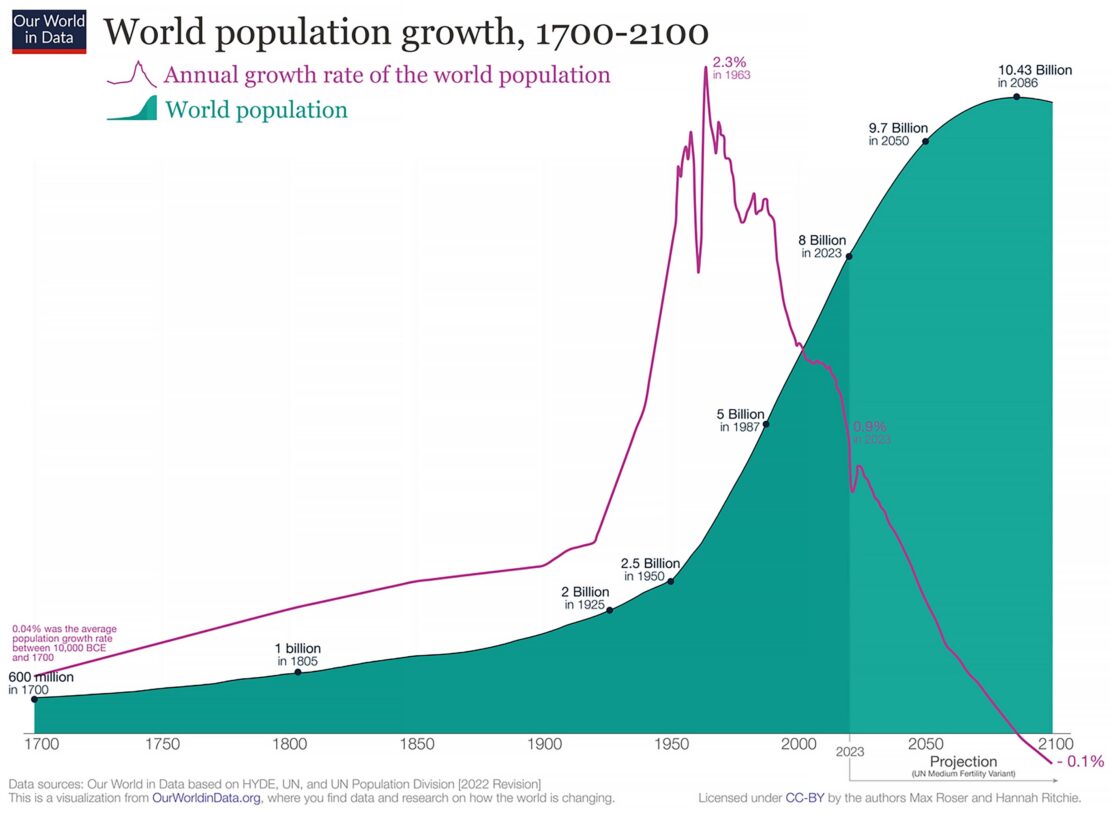

Continuous population growth, which many of us have grown up with and heard about for years, is beginning to plateau. Considering the world reached 8 billion people in November 2022, slowing birth rates might not seem obvious, but the growth rate is starting to slow down as countries continue to develop.

The United Nations still predicts that the global population will continue to increase (if somewhat slower than it was previously) to 10.4 billion by 2100. Other organizations, using the same data as the United Nations, see a much darker reality past the plateau of 10.4 billion, where the world’s population reaches a peak in 2086 before beginning to decline:

The United States Census Bureau has similar findings to Our World in Data and attributes the decline to lower fertility rates in developed and developing countries. One of the reasons for the discrepancy between studies can be attributed to the lack of accurate vital statistics in some areas of the world, including infant mortality, making predictions difficult. However, most studies show that this decline in population growth, combined with increased life expectancy due to medical advances, is expected to lead to a doubling of the world’s population over the age of 65 — from 10% today to approximately 20% by 2060. As a result, there will be unprecedented structural changes in labor markets and in economies built on the assumption of continued population growth.

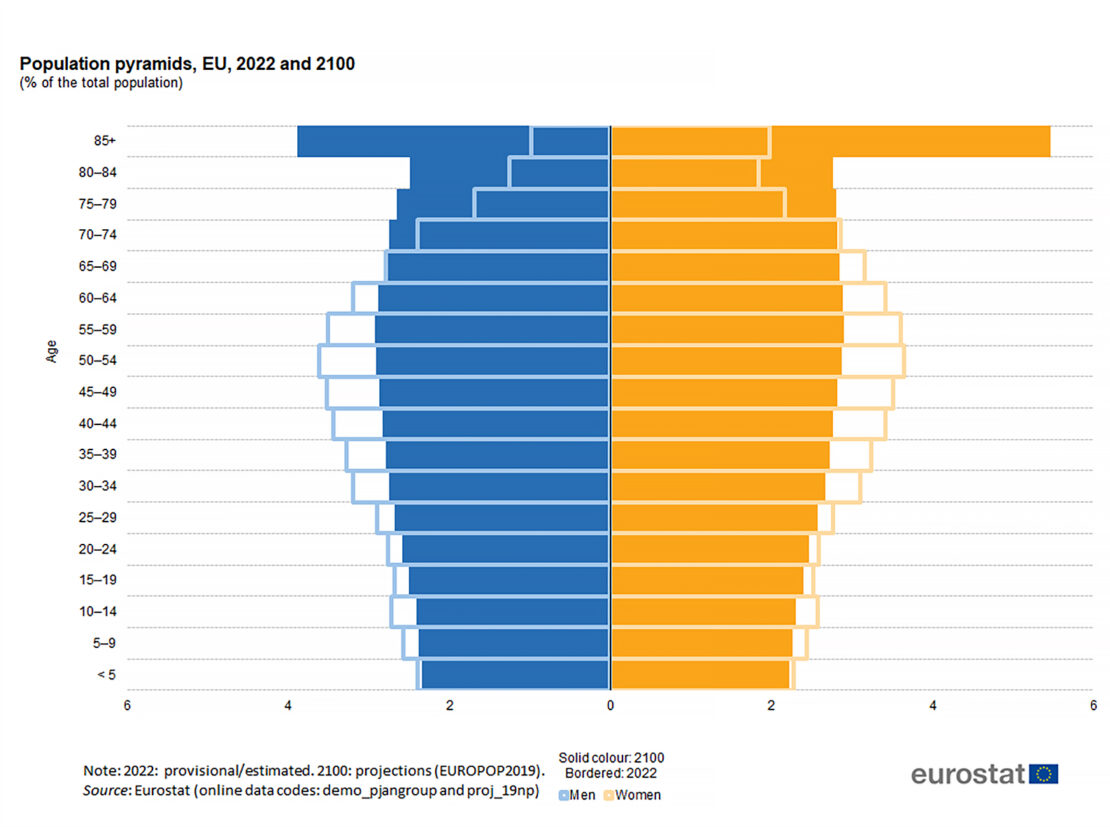

Europe has already experienced this population plateau, even with increasing migration and reduced visa requirements. While immigrants can help mitigate declining birth rates, without additional strategies like the adoption of automation and digitalization countries won’t be able to prevent the worst of the coming global labor shortage. Over time, these technologies will become essential to fighting the harsh reality of 2100 (solid bars) compared to 2022 (transparent bars), when Europe’s population pyramid is predicted to look like a rectangle with a hat on top:

Currently, only 6.1% of Europe’s population is over the age of 80, and that number is expected to more than double to 14.6% by 2100, while the percentage of people over the age of 65 will increase from 20.1% to 31.3%. Without automation and new technologies to combat this upcoming crisis, in less than 80 years Europe is likely going to face a future eerily similar to what their Japanese counterparts are currently facing due to rapid population decline. For reference, Prime Minister Fumio Kishida said in January 2023, as a response to Japan’s aging population, that “Japan is standing on the verge of whether we can continue to function as a society.”

In addition to an aging workforce, current education levels in European countries such as Germany are also stagnating, preventing some from filling empty positions at all. Educational stagnation goes alongside an increase in manufacturing job vacancies, which has increased by 111.2% from Q1 2020 to Q3 2022. The rise in vacancies also coincides with the rise of industrial robots in the industry, pointing to a future where humans work alongside robots rather than being replaced by them.

First, what are industrial robots?

Industrial robots are automated machines designed to perform manufacturing and production tasks that are often too difficult, dangerous, or repetitive for humans. While these robots once had fixed positions in a factory, they are now increasingly able to work autonomously with the help of artificial intelligence that helps them sense and navigate their surroundings safely.

These industrial robots will play an important role in filling positions in a declining workforce as the population begins to age. In the future, AI-powered robots will work alongside human counterparts and factory machines to automate tasks or parts of tasks that would otherwise have been performed by humans. These are not radical tasks either, but simple processes like moving goods within a factory, retrieving tools from other workspaces, and rotating objects, among other roles.

Most industrial robots used in manufacturing processes are also likely to be designed to reduce worker stress, with the added benefit of making manufacturing jobs more attractive than they are today. This includes incorporating robots into processes such as material handling, where machines will be responsible for loading and unloading containers instead of having human teams do the same through physical efforts. Another application for robotic manufacturing processes is for inspections, where robots can continuously monitor machines to collect data, which can later be used to create a digital twin of operations. This data can then be used to predict machine maintenance and downtime.

How fast are AI-powered robots being adopted?

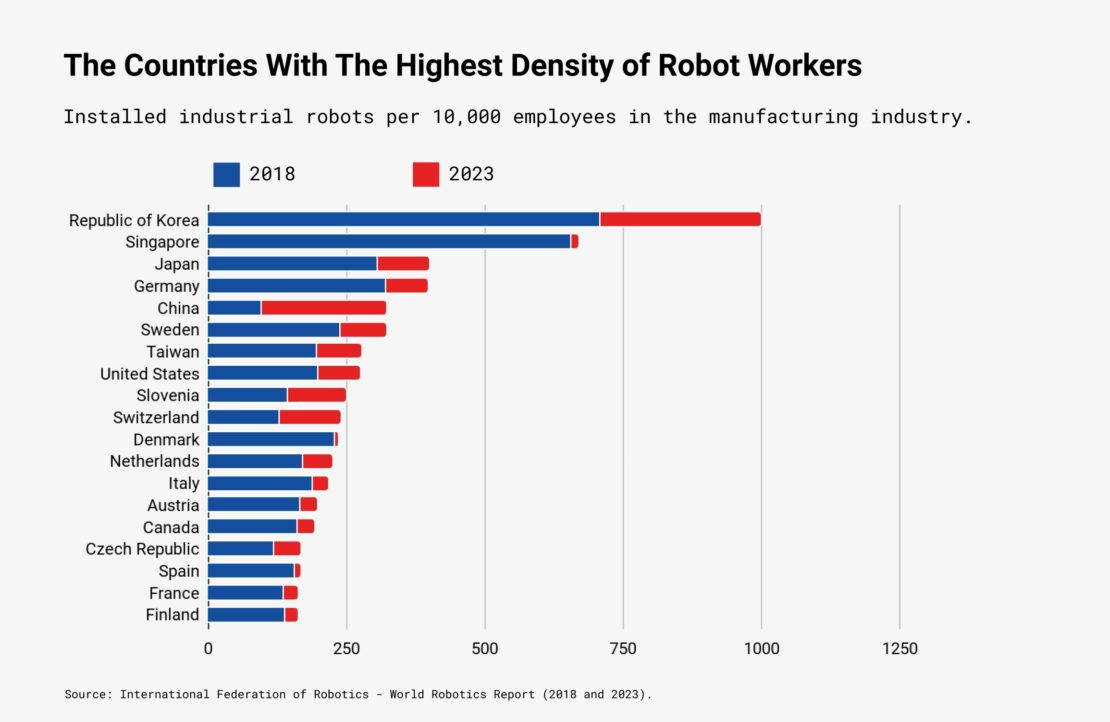

Comparing the 2018 World Robotics Report to the most recent 2023 report, we can see significant shifts in industrial robot adoption, including countries that were once smaller players moving up the ranks and proving themselves to be sleeping giants.

In addition to countries like China significantly increasing their adoption rates, current leaders like Singapore, which had one of the highest robot densities in 2018, barely increased adoption at all, putting them at risk of losing their current leadership in the field if countries like China continue to increase at the present rate. The Republic of Korea, on the other hand, has continued to steadily increase the number of autonomous robots per employee, bringing them to the highest rate in the world of 1,000 industrial robots per 10,000 employees. For other countries, such as Japan, with an increase of 308 to 299 industrial robots per 10,000 workers from 2018 to 2023, or Germany, with an increase of 322 to 297 industrial robots per 10,000 workers from 2018 to 2023, it seems like they have adopted a slow and more standardized installation rate that runs the risk of not keeping up with production needs if the number of job vacancies in both countries continues to rise.

The projections in the 2018 World Robotics Report indicated that there would be a considerable increase in robot installations in 2020, which likely didn’t happen due to the pandemic and the economic uncertainty that followed. The forecast estimated annual global industrial robot installations would increase from 381,000 units in 2017 to 553,000 in 2020 and 630,000 in 2021, respectively. In reality, there were only 390,000 installations in 2020 and 526,000 in 2021. This adjustment went from predicting a 30% year-over-year growth rate to about 7% in 2023.

This lower adoption rate may also have much to do with the changing attitudes toward industrial robots. In an August 2022 study by McKinsey, they found that the main challenge to adoption was the high cost (71%), as well as a lack of corporate experience with automation (61%). This included a low confidence level in these technologies, making it more difficult to finance such initiatives. Furthermore, there was a fear of laying off workers due to automation, which discouraged companies from implementing technology that could potentially leave parts of their workforce unemployed, despite the fact that these robots tend to result in a change in roles rather than the creation of redundancies.

How has artificial intelligence changed adoption rates?

It’s hard to underestimate the impact that artificial intelligence is expected to have on adoption rates. Much of this has to do with the ease of implementation, as AI conversational assistants are easier to use because they work through natural language processing (NLP). These natural language models can create dashboards and program the robots to act as needed without requiring a dedicated software developer on the team.

Robotics companies are also seeing this shift and are beginning to focus heavily on developing AI to ease installation for manufacturers. This includes robotics companies like Sarcos, who recently made this public announcement about their shift to AI-powered robots:

After continued extensive analysis of our business that led to a deeper understanding of the risks and work necessary to bring our robotic systems to market, we determined that our AI software platform offers the greatest risk-adjusted revenue opportunity for the company in the near- and mid-term. We believe that our AI software platform will enable, for the majority of the industrial robots being sold around the world, a dramatic reduction in robotic training times while also making industrial robots far more agile, meaning they can perform more tasks with greater variability similar to how humans can perform a wide variety of tasks.

Sarcos has been making industrial robots since 1983 and has developed decades-long strong relationships in the industrial sector. Their standing as a leader in the industry sends a clear signal that AI-powered industrial robots are the only clear way forward. Other robotics companies, such as Gecko Robotics, have followed suite by using a mix of artificial intelligence and mobile industrial robots to analyze data and recommend maintenance schedules. This is done through their software called Cantilever, a crawling Gecko robot that moves around a particular structure to collect data before sending it off for analysis. The customer can then see recommendations for future maintenance and the associated risk, thanks to automated AI recommendations.

Startups building AI-powered industrial robotics solutions in 2024

As the world moves to increase the adoption rate of industrial robots to ease the strain on an aging global workforce, some startups are making strides in developing technologies designed to make adoption easier. This includes new advancements in the manufacturing robotics industry, as well as the creation of new software to simplify installation and interaction between robots and humans.

Here are some major startups to watch out for in 2024:

Founded in 2017, Fruitcore Robotics uses artificial intelligence-powered assistants to power its industrial robots, allowing users to create dashboards and new actions that automate industrial processes. They recently announced HorstOS, the software used to program each of their three robotic arms, designed for machine maintenance, parts separation, and quality inspection, among other use cases.

Founded in 2019, Neura Robotics has already released several AI-powered robots, including an intra-logistics solution called the MAV 500, which can autonomously transport objects from one location to another in a busy factory setting. While the MAV may look small, it weighs 300 kg and can transport heavier objects than traditional AMRs (autonomous mobile robots).

Founded in 2021, Mujin is a Japanese provider of AI-powered industrial robots, including a universal robot controller, a depalletizing arm, and TruckBot, which can unload trucks and containers at a rate of 1,000 cases per hour, according to their CEO.

Founded in 2020, Relocalize has created autonomous mobile mini-factories equipped with robots that can package ice and will soon expand to beverages. The idea behind the company was that the CO2 required to create, transport, and store ice from the original facility results in unnecessary carbon emissions. Using local resources while making and packaging the ice on-site allows for a more sustainable supply chain for ice production.

Want to be the next startup to bring the latest AI-powered industrial robotics solution to the logistics industry? Pitch us a robotics-related problem — we might just help you create the startup to solve it.