The European pre-pandemic retail industry has been estimated to register €49 billion in inventory shrinkage-related losses. Around 26%, or €13 billion of those, occurred online. Indeed, inventory shrinkage is, unfortunately, a term that any e-commerce seller will become acquainted with early on in their journey as a combination of fraud, breakage, and warranty return will inevitably prevent all the acquired inventory from being sold. It’s reflective of a problem that calls for innovative solutions to inventory management in a world where warehouse automation is increasingly tailored towards speedy order fulfillment.

What is inventory shrinkage and why is it important?

Inventory shrinkage, which is also simply known as inventory loss, is a term that refers to the precise quantity of inventory that doesn’t get sold. Retail loss prevention is responsible for identifying shrinkage and following up with solutions to the rampant problem. Traditional loss prevention solutions such as the hiring of security guards and the installation of security cameras can be costly and only tackle one part – the offline part – of a wider, digitizing problem.

With 43% of retailers listing inventory management as their biggest obstacle towards running a successful e-commerce store, it’s clear that the sometimes gargantuan task of storing, sorting, and keeping inventory safe is a top priority for many businesses. 50% of US retail decision-makers also say inventory misjudgments prevented them from making more full-priced sales, showing that there is ample space for innovations that will save costs when it comes to the steep prices of inventory management solutions.

Not a new trend – shrinkage has been an issue long before COVID

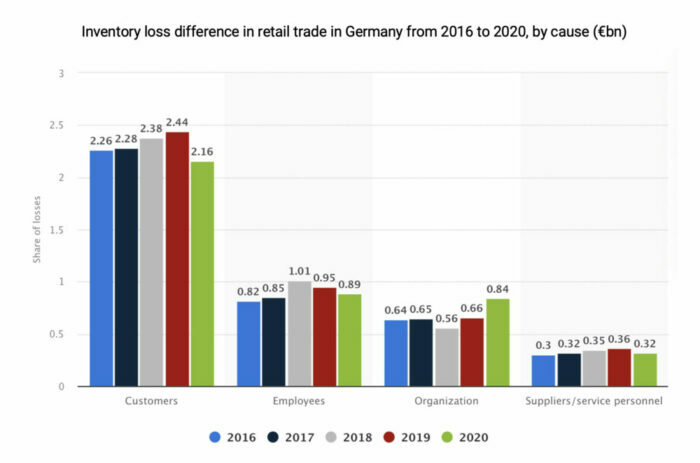

Though Covid-19 has undeniably had a great impact on inventory management, particularly in the realm of e-commerce, issues with management systems have prevailed since before the pandemic struck. A lack of real-time inventory solutions means that inventory overstock and understock have contributed to millions in losses in recent years. As an example, the United States Census Bureau showed that for every dollar sold, businesses hold $1.39 worth of inventory, which constitutes a 10% increase over the last decade. Similarly, German retailers lose 1.43% of revenues to shrinkage every year, although that still sits below the European average, which sits at 1.83%. The EHI Retail Industries chart below shows that customers accounted for a rising share of losses before a slight decrease in 2020 caused by the pandemic.

Source: Statista

Blockchain, AI, and warehouse automation can flatten the shrinkage curve

Innovations to help businesses optimize inventory management and reduce losses are coming in various forms. AI, predictive analytics, distributed inventory, warehouse automation, and blockchain solutions are making their mark. Walmart and Nestlé, for example, use the IBM Food Trust blockchain to ensure food safety and freshness and minimize waste across the supply chain.

With return delivery costs reaching a staggering $550 billion in the US in 2020, blockchain solutions can help to keep a distributed ledger of the entire cycle of products across various industries, helping sellers to keep track of their goods, keep a clear record showing whether damage was incurred before or after a return, and take the required action. Increased automation across warehouses (the market is expecting a growth of 38.4 percent in 2021), meanwhile, will mean fewer workers on the warehouse floor and less opportunity for human error and foul play. Such solutions will not completely reverse the trend on inventory shrinkage, though they can help to vastly reduce the massive losses incurred on a yearly basis by sellers worldwide.